The auto industry has always been about innovation, but 3D printing is pushing the boundaries like never before. Imagine cars being built faster, cheaper, and with custom designs tailored to each driver. With sustainability, efficiency, and performance at the forefront, 3D printing is set to revolutionize manufacturing the way Netflix transformed entertainment. Buckle up, because the future of car production is looking more like science fiction every day!

Faster Production with On-Demand Manufacturing

3D printing eliminates the long wait times of traditional manufacturing processes. Parts can be printed on demand, reducing delays and supply chain disruptions. This accelerates production timelines for both automakers and consumers. Just like streaming replaced physical DVDs, 3D printing is cutting out unnecessary steps.

Reduced Manufacturing Costs and Material Waste

Traditional car manufacturing involves expensive molds, tools, and excess materials. 3D printing minimizes waste by using only the exact amount of material needed. This significantly lowers production costs while making manufacturing more eco-friendly. It’s like digital downloads replacing wasteful CD production in the music industry.

Customization at an Unprecedented Scale

3D printing allows automakers to design cars tailored to individual customers. From personalized interiors to custom exterior panels, drivers can get exactly what they want. This level of flexibility was impossible with traditional assembly lines. Just like streaming services offer personalized content, 3D printing offers personalized vehicles.

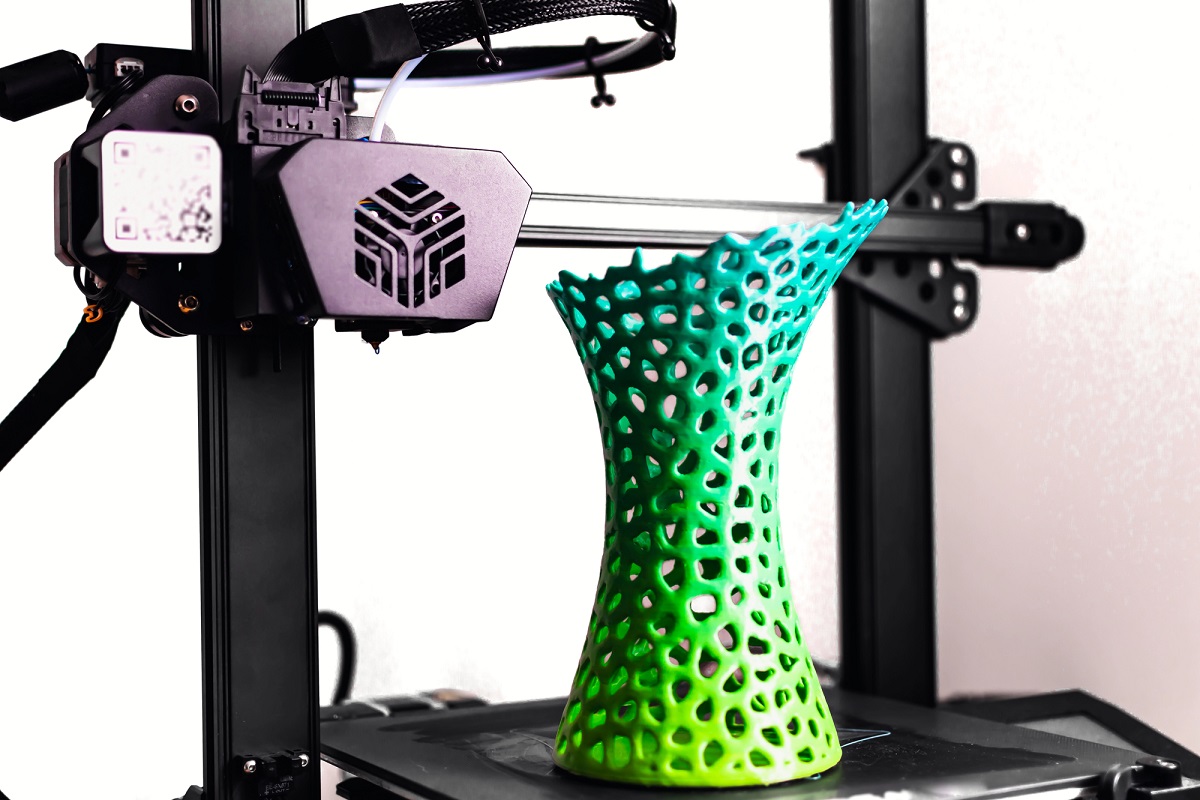

Lighter Vehicles for Improved Fuel Efficiency

3D-printed parts can be designed with intricate, lightweight structures without sacrificing strength. Lighter cars mean better fuel efficiency, lower emissions, and enhanced performance. This is especially valuable as the industry shifts towards electric vehicles. Just like slim laptops replaced bulky computers, lightweight cars are the future.

Related: 14 Mind-Blowing Car Features Inspired by the Cybertruck That You Can Get Now

Faster Prototyping and Innovation Cycles

Automakers can test new designs rapidly by printing prototypes instead of waiting for expensive tooling. This speeds up research and development, allowing for more frequent innovation. Companies can quickly refine designs and introduce new models faster than ever. It’s just like how digital content creation made rapid iterations possible in media.

Related: 13 Genius Things to Keep in Your Car That Will Make Your Life So Much Easier

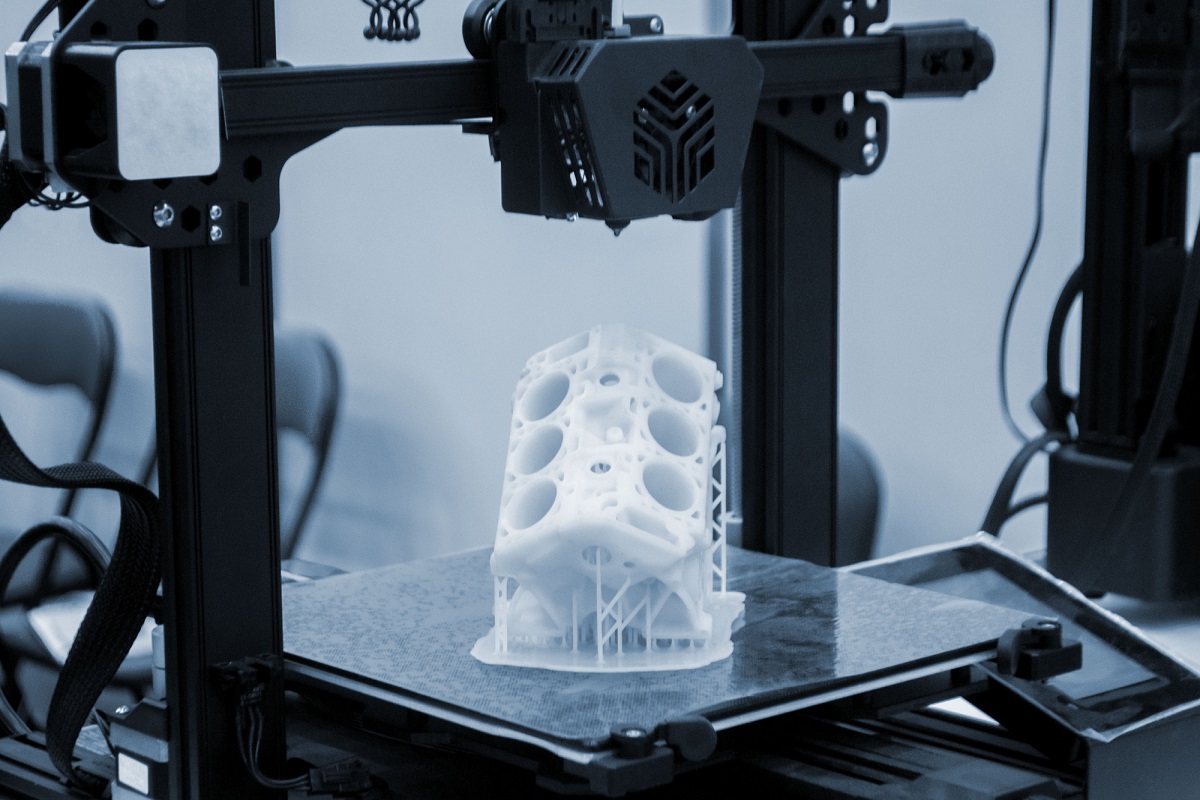

Stronger and More Durable Car Parts

3D printing isn’t just about plastic, it can produce high-strength metal and composite parts. This results in components that are lighter, yet just as strong or even stronger than traditionally manufactured ones. Improved durability means fewer breakdowns and longer vehicle lifespans. Just like stronger smartphone glass revolutionized durability, 3D printing is enhancing car resilience.

Related: 12 Weird Ways Your Car Reveals More About You Than You Think

Greater Supply Chain Resilience

Traditional manufacturing relies on complex global supply chains that can be easily disrupted. 3D printing enables localized production, reducing reliance on faraway factories and vulnerable shipping routes. Automakers can print parts closer to consumers, reducing delays and costs. It’s like how streaming eliminated the need for physical distribution centers.

Related: 13 Smartest First Car Choices Millennials Can Make Without Regret

Sustainable Manufacturing with Recycled Materials

Many 3D printing processes can use recycled plastics and metals, reducing the demand for raw materials. This supports the industry’s push toward sustainability by lowering carbon footprints. Waste reduction and resource efficiency make 3D printing an eco-friendly solution. Just like digital books replaced millions of printed copies, 3D printing reduces material waste.

Related: 15 Nostalgic ’80s & ’90s Cars That Are Making A Comeback

Easier Repairs with Locally Printed Parts

Car repairs often involve waiting weeks for replacement parts from manufacturers. 3D printing allows mechanics to print parts on-site or locally, drastically cutting repair times. This reduces vehicle downtime and eliminates long shipping delays. It’s just like how 3D-printed medical implants revolutionized healthcare by providing instant solutions.

Related: 15 Cars That Defined Boomer Childhoods and Are Now Ultimate Collectibles

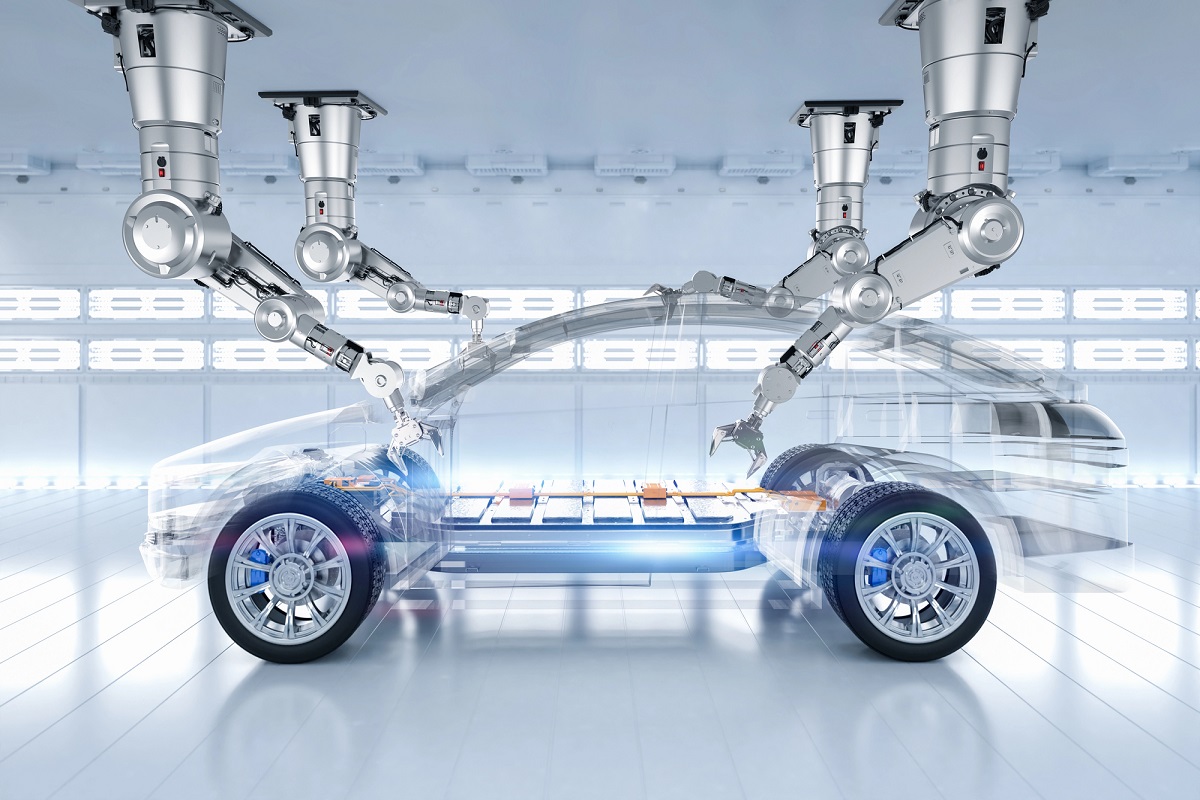

A Game-Changer for Electric Vehicle Production

EV manufacturers can leverage 3D printing to create lightweight battery casings, motor components, and aerodynamic designs. The technology enables faster innovation in EV development, enhancing range and performance. 3D printing accelerates the transition to a fully electric future. Just like fast-charging transformed EV usability, 3D printing is optimizing production.

Related: 12 Used Car Buying Mistakes That Could Cost You Thousands Overnight

Enhanced Safety with Complex Geometries

3D printing enables the creation of intricate structures that absorb impact better than traditional designs. These complex geometries enhance crash resistance and vehicle safety. Stronger, smarter designs mean better protection for drivers and passengers. Just like airbags revolutionized car safety, 3D printing is improving vehicle resilience.

Related: 13 Costly Driving Blunders That Are Putting You at Risk

Lower Costs for Limited-Edition and Luxury Models

High-end cars often require custom, low-volume parts that are expensive to manufacture traditionally. 3D printing eliminates the need for costly molds, making limited-edition and bespoke models more affordable. This allows luxury brands to experiment with unique designs. Just like custom sneakers became more accessible, high-end cars are getting a manufacturing makeover.

Related: 12 Car Repairs Mechanics Don’t Want You to Know

Reduced Need for Large Factories and Warehouses

Because 3D printing is decentralized, automakers could reduce reliance on massive assembly plants. Smaller, local production facilities could print cars or parts as needed, cutting logistics costs. This would transform the entire manufacturing landscape. Just like online shopping reduced the need for big retail stores, 3D printing could shrink auto factories.

Related: These 15 Cars Ruled Their Time and Became Cultural Phenomena

Military and Emergency Vehicles Produced On-Demand

The military and emergency response teams can benefit from 3D printing for mission-critical vehicles. Instead of waiting months for specialized parts, they can print replacements on-site. This enables rapid deployment of customized vehicles. Just like drones revolutionized military operations, 3D-printed vehicles could redefine mobility.

Related: 12 Legendary Video Game Cars That Are Shockingly Real

The auto industry is on the verge of a transformation, and 3D printing is leading the charge. With faster production, lower costs, and unlimited customization, traditional car manufacturing could soon become obsolete. Whether it’s electric cars, luxury vehicles, or off-world rovers, the future is being printed, layer by layer. The question isn’t if 3D printing will take over auto manufacturing. It’s when.

Disclaimer: This list is solely the author’s opinion based on research and publicly available information.

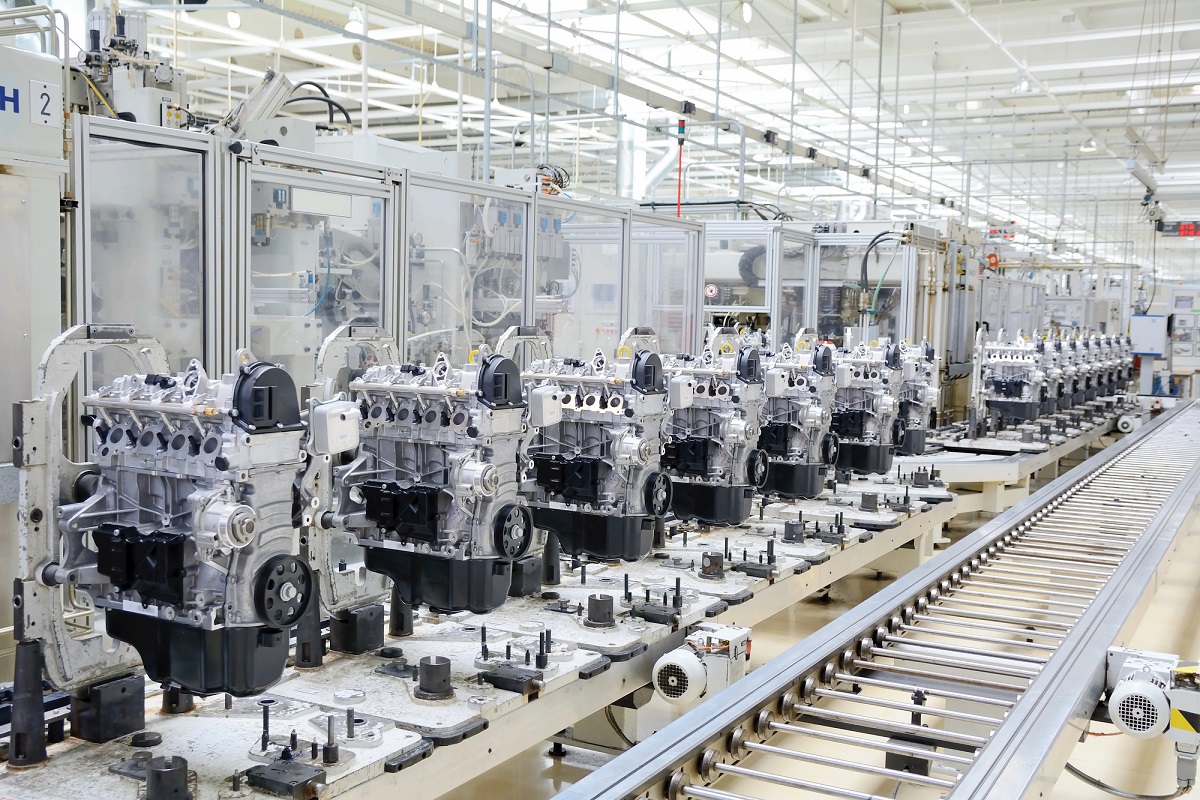

12 Shocking Facts About How Robots Are Changing Car Manufacturing Forever

Automation has taken over car manufacturing in ways that were unimaginable just a few decades ago. Robots are now assembling vehicles with mind-blowing precision, improving safety, and even making real time decisions on the production line. These 12 shocking facts prove that car manufacturing will never be the same again.

Read it here: 12 Shocking Facts About How Robots Are Changing Car Manufacturing Forever

13 Insane Ways Scientists Are Growing Car Parts Like Living Organisms

The future of automotive manufacturing is undergoing a radical transformation with the introduction of bioengineered car parts. Scientists are harnessing the power of living organisms to create stronger, more sustainable, and self-repairing materials for vehicles. This innovation reduces environmental impact, cuts production costs, and enhances vehicle longevity.

Read it here: 13 Insane Ways Scientists Are Growing Car Parts Like Living Organisms

11 Eco Friendly Materials That Are Revolutionizing Car Design

As sustainability becomes a top priority in the automotive industry, manufacturers are turning to innovative, eco-friendly materials to reduce their environmental impact. These materials enhance fuel efficiency, minimize waste, and promote recyclability without compromising safety or performance. From plant-based alternatives to recycled components, here are 11 groundbreaking materials shaping the future of car design.

Read it here: 11 Eco Friendly Materials That Are Revolutionizing Car Design

You’ll love these related posts:

- 15 Game Changing Car Tricks That Will Transform How You Drive

- 12 Most Unforgettable Movie Cars That Every Fan Wishes They Owned

- 13 Weirdest Things That Secretly Raise Your Car Insurance Rates

- 13 Brilliant Driving Hacks Every Car Owner Needs to Try Right Now

- 12 Expensive Cars That Promise Luxury But Will Leave You Disappointed